Fans, Service life, MTBF

Technical infos

The service life of a fan depends on many factors

As fan manufacturers provide vague information, it is often difficult to make comparisons at a glance. The varying units of measure used worldwide for pressure and flow rate frequently do not allow a comparison to be made and can result in the distortion of a precise assessment of the quality.

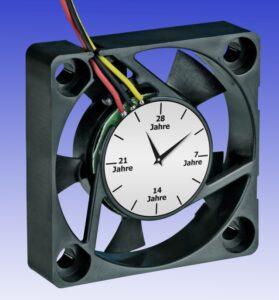

The service life of a fan depends on many factors. The figure often mentioned in the data sheets as the service life is a survival probability that is calculated as the average taken from a large quantity. In order to interpret this information correctly you must be aware of the conditions that are used for determining this statistical value.

1. probability factor (L1, L10 or MTBF)

The probability factor states the percentage of fans (determined from a very large test quantity) that can fail after the stipulated time. L10 for example, means that 10% will fail after n operating hours and 90% will survive.

L1 is hardly used for fans, however the MTFB is frequently stipulated. This is the mean time between two failures. As the first error is equivalent to the failure as far as fans are concerned, the correct term should actually be MTTF (Mean Time To Failure). After the time stipulated as MTTF, 63% parts have failed.

L1, L10 and MTBF are statistical data that can only be determined by observing larger

quantities. With the individual delivery lots, a

typical deviation can occur in both directions. Only when many delivery lots are evaluated, will the correlation with the prediction be adequate. As the service life probability (MTBF) of modern fans lasts several decades, an actual

measurement carried out over this period is

neither possible nor meaningful. Measurements are therefore made over a considerably shorter period and extrapolated. The values L1, L10 and MTBF are roughly as follows:

L1 : L10 : MTBF ≈ 0.21 : 1 : 4

2. Operating temperature

The failure probability increases logarithmically with the temperature. If not otherwise stipulated, the service life data in the SEPA data sheets refer to 40°C. Other manufacturers also often publish the considerably higher values at ambient temperature.

3. Operating time

The service life of fans always refer to continuous operation. In the case of intermittent operation, the fan is not operated continuously but cannot cool down fully during stoppages. In the case of short-time operation, the stoppages last long enough for the fan motor to cool down fully. Intermittent and short-time operation stress the fan resulting in reduction of the service life. Short-time operation is therefore only recommended when the fan is seldom required.

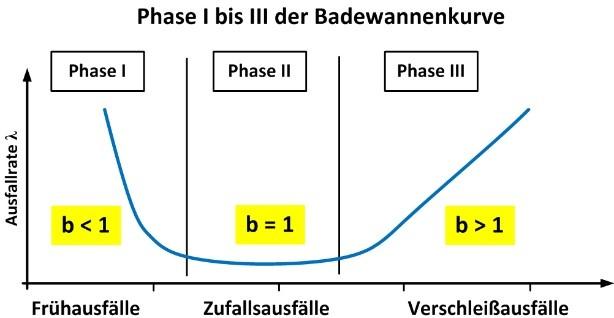

4. Failure rate

Failures do not occur consistently within the service life. In the case of larger quantities, increased numbers of parts will initially fail (premature failures). The failure rate later reaches a relatively low, virtually constant value up to the end of the service life when the failures increase sharply. The relation of the failures over time can be illustrated in a bathtub curve. In order to minimize particularly annoying premature failures, the SEPA fans are subjected to a stress test lasting several hours at high temperature.

5. Ball bearing or sleeve bearing?

The bearings of the motor shaft represent the decisive service life element in the fan. Two completely different bearing systems are used – ball bearings and sleeve bearings. Formerly used mixed bearing systems do not offer any advantage. The rotor speed does not influence the

service life probability.

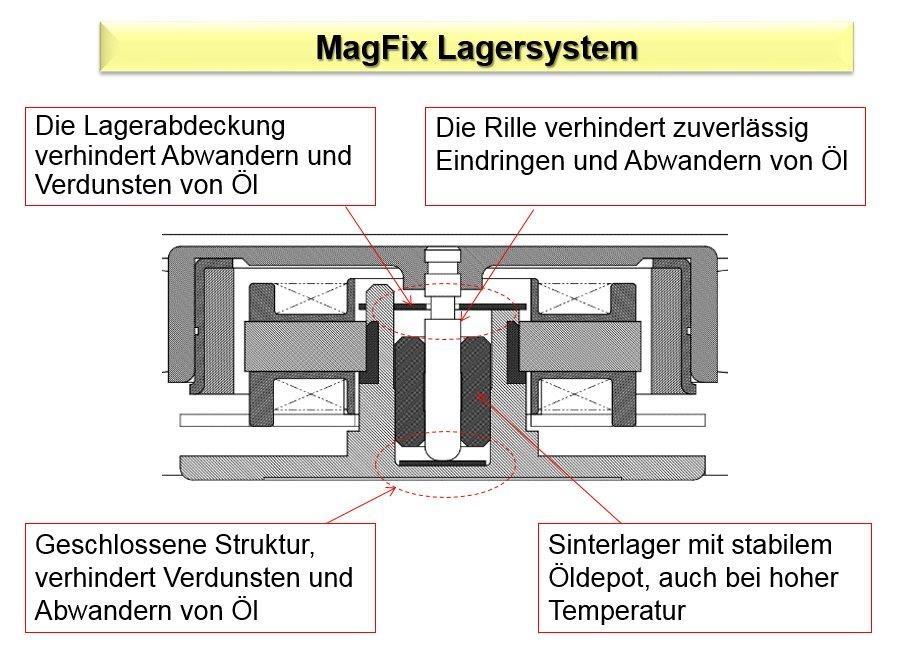

The sleeve bearing systems comprise a sintered bearing tube of oil-impregnated bronze (permanent lubrication). In the past, sleeve bearings were often extremely unstable due to uncontrolled loss of oil and caused frequent failures. The modern fans of SEPA EUROPE however, are equipped with a MagFix® sleeve bearing. This type of bearing constructively prevents migration of the lubricant guaranteeing stable lubrication throughout the entire service life. These inexpensive fans equipped with magnetic shaft fixation (MagFix®) can be used for a wide temperature range and are extremely resistant to vibration and impact.

Pre-tensioned ball bearings are used for extreme requirements as far as temperature and reliability are concerned. The ball bearings have polished running surfaces and are permanently lubricated with a wide range grease. The migration of the lubricant and penetration of dust is prevented by two cover plates.

6. Drive

DC fans are always brushless. The English term “brushless fan” is often used in this context. Commutation is an electronic process and that does not require “brushes” which is the case with simple, low-priced DC motors found for example in some cordless screwdrivers or drills. The electronic commutation is thus contactless and is therefore not subject to the same mechanical wear of brushed DC motors. AC fans have no commutation. The torque is generated via a phase shift in the motor and there is also no mechanical wear at this point.